Capacity:......

Introduction:The sand making machine produced by our company has many names in the use of users all over the country. Some places are called composite crusher, some are call.....

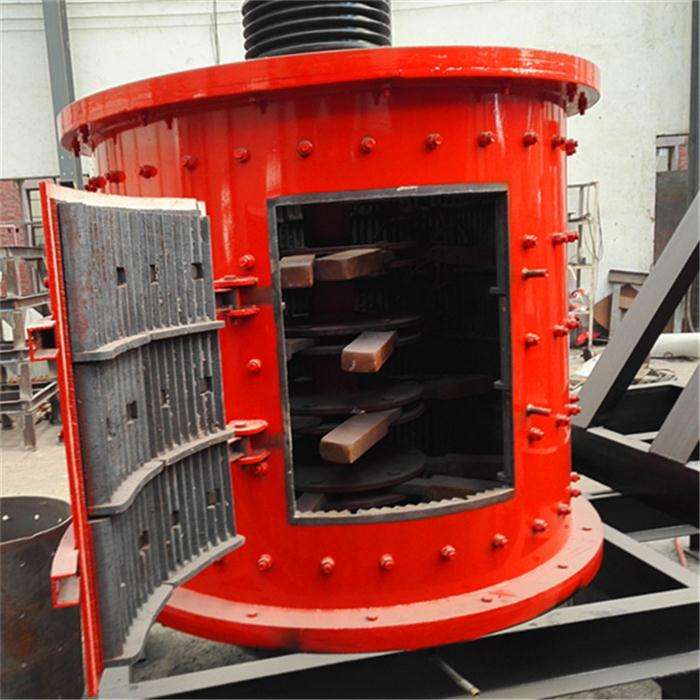

The sand making machine produced by our company has many names in the use of users all over the country. Some places are called composite crusher, some are called sand making machine, and some are called composite breaking machine. China has a vast territory and rich resources, and different cultures have different names for this equipment. However, no matter how it is called, it is the same product and a common sand making host in the sand making industry. It is a fine crushing and coarse grinding product that integrates similar crusher technologies and designs the main technical parameters. It is mainly used to crush cement raw meal and clinker in medium-sized cement plants. It provides an ideal fine crushing equipment for technical transformation of cement plants or new cement production lines. It is also suitable for iron ore, sandstone, gypsum, blast furnace slag, coal gangue Crushing of lump coal and other medium hard ores.

The materials vertically fall into the high-speed rotating impeller from the upper part of the machine. Under the action of high-speed centrifugal force, they are separated with another part in the form of umbrella. The materials around the impeller produce high-speed impact and crushing. After the materials collide with each other, they will form eddy currents between the impeller and the casing, collide and rub with each other for many times, and discharge directly from the lower part, It forms a closed circuit for many times and is controlled by the screening equipment to achieve the required particle size of the finished product

The sand and gravel production line exported by our company to North Korea has begun production

North Korea’s sand and gravel production line equipment has begun large-scale production. The sand and gravel p...Sent to Sichuan 30m mesh belt dryer

The 30-meter long mesh belt dryer sent to Sichuan began to be loaded and shipped. The mesh belt dryer is a special dr...The pressure ball drying production line with an annual output of 200,000 tons is sent to Yuncheng,

The production line is fed by a loader to the production line, and is conveyed to the mixer via a belt conveyor to ...Delivery site of the flap dryer production line ordered by a customer in Yulin, Shaanxi

Our company is a mechanical enterprise mainly engaged in the production of ball pressing and drying equipment. The ...

Copyright © HENAN FUWOLIQIANG mechanical equipment Co., Ltd