Capacity:......

Introduction: The metal shredder is a new generation product produced by our company. The metal crusher not only improves the production capacity and crushing efficiency, b.....

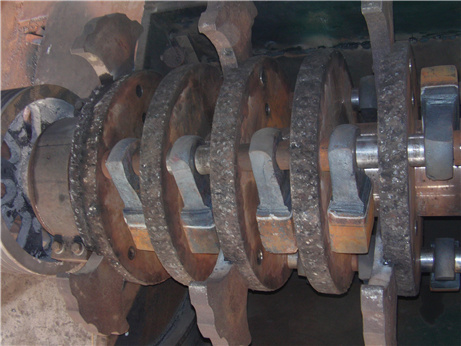

The metal shredder is a new generation product produced by our company. The metal crusher not only improves the production capacity and crushing efficiency, but also expands the scope of application. The metal crusher produced by our factory is a fine crushing crushing machine. This series of metal crusher products absorb the advantages of various crushers and make full use of impact , Shearing, mutual impact, grinding and other theories are carefully developed. After years of research, the metal shredder equipment produced by Henan Fuvoliqiang Machinery has surpassed that of the same industry.

1. Geared motor drive.

2.The meshing blade can completely break the can.

3. Use special blades, the blade hardness is not less than HRC55 (the HRC hardness of the file is 51 degrees)

4.Strong structure, densely distributed reinforcing ribs to ensure the strength of the box.

5.Automatic button control, safe and convenient.

6.Safety signs and safety labels to ensure safe use.

7. It can be equipped with conveyor belt for feeding.

| model | Type 600 | 800 type | 1000 type | Model 1300 |

| Main engine power (kw) | 18-22 | 30-45 | 45-55 | 75-90 |

| Output (kg/h) | 600-800 | 800-1200 | 1200-1500 | 6000-10000 |

| Land area (m2) | 7 | 9 | 12 | 15 |

| Host size (m) | 2.6x1.6x1.25 | 2.9x2.1x1.5 | 3.2x2.5x1.9 | 3.5x2.8x2.2 |

1 Before starting the test run, strictly check whether the installation of each part of the machine meets the requirements, whether the screws and bolts are loose, you can gently pull the belt to try it out, and whether there is any phenomenon such as bumping the shell. At the same time, check the direction of rotation, and it is strictly forbidden to crush flammable and explosive materials to avoid accidents.

2 During production, uniform cutting should be maintained to ensure the crushing quality and normal production. At the same time, it is strictly forbidden to overload the motor to ensure the normal operation of the machine.

3 In addition to checking the fastening and loosening of various parts frequently, attention should be paid to checking the wear and tear of the wearing parts. If the wear is serious, it should be replaced in time to avoid damage to the main components. And take necessary fire prevention measures.

4 Due to the high speed, in addition to the correct and firm installation, good lubrication should be maintained at the same time to maintain the normal operation of the machine. Under normal circumstances, it is normal that the bearing temperature does not exceed 70 degrees. Add butter and molybdenum disulfide to the bearing of the main engine once a week, and the effect of high-speed butter is better.

The sand and gravel production line exported by our company to North Korea has begun production

North Korea’s sand and gravel production line equipment has begun large-scale production. The sand and gravel p...Sent to Sichuan 30m mesh belt dryer

The 30-meter long mesh belt dryer sent to Sichuan began to be loaded and shipped. The mesh belt dryer is a special dr...The pressure ball drying production line with an annual output of 200,000 tons is sent to Yuncheng,

The production line is fed by a loader to the production line, and is conveyed to the mixer via a belt conveyor to ...Delivery site of the flap dryer production line ordered by a customer in Yulin, Shaanxi

Our company is a mechanical enterprise mainly engaged in the production of ball pressing and drying equipment. The ...

Copyright © HENAN FUWOLIQIANG mechanical equipment Co., Ltd