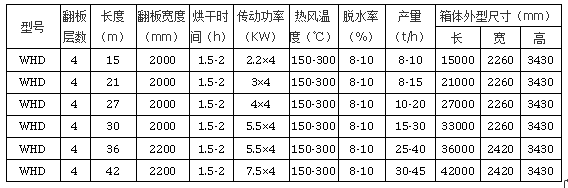

Capacity:10-40 tons/hour......

Introduction: The flap dryer is a kind of horizontal dryer. Drying equipment based on the principle of two-way conveying. The material flows from the head of the dryer thr.....

The flap dryer is a kind of horizontal dryer. Drying equipment based on the principle of two-way conveying. The material flows from the head of the dryer through the feed hopper into the upper grid of the dryer. The feed hopper has the function of buffering and uniform distribution of the material. The material is evenly distributed on the grid, and the thickness of the material is 100mm-200mm. It runs smoothly to the end of the dryer, and the special flap mechanism of the flap dryer unloads the material into the lower layer smoothly, and then slowly runs to the head of the dryer, repeating this cycle, and shuttles inside the dryer many times. In operation, the distribution of materials in the dryer is more even and reasonable, and the hot air baking time is longer. After the materials are dried, they will be sent out from the tail of the machine.

1. The special turning mechanism makes the distribution of the material in the dryer more layers, the layering is even and reasonable, and the inner layer that cannot be used by other methods such as the mesh belt dryer is effectively used, which extends the drying of the material. The internal running length of the machine makes the material bake by hot air longer and the drying effect is more thorough.

2. The material of the flap is made of heat-resistant steel plate punched into a mesh shape, which has high strength, is not easy to deform, and has good air permeability. Chain rollers are connected to both sides of the flap. The unique flap structure ensures that the rollers on both sides are coaxial and facilitates later maintenance, disassembly and installation.

3. The guide rail adopts a specially processed track, which is optimized according to the material characteristics and fabric characteristics to ensure its straightness and strength, and the sprocket running resistance is small. The turning mechanism completed by the guide rail can ensure that the turning plate can be tilted freely. , To ensure that the material maintains a small damage rate.

4. The sprocket adopts an automatic tensioning device, the chain plate runs smoothly, and a good guide rail can effectively solve the phenomenon of chain drop, chain jam, and deviation.

5. The running speed of the chain plate can be adjusted according to the actual conditions such as season and weather. Using electromagnetic speed regulation or frequency conversion speed regulation transmission, the operating speed can be adjusted according to the actual needs of the production site, and the drying time can be controlled.

6. Equipped with temperature control devices. Temperature measuring devices are installed on both sides of the dryer's head, middle, and tail, and digital display is realized, so that the operator can grasp and control the temperature in the box in time, and the flue air inlet design There is a smoke gate, once the machine fails, the heat source can be immediately cut off to prevent fire.

7. According to the water content of the material and the characteristics of the material, the air is divided into points and the air is distributed between layers. The hot air is evenly distributed, which can effectively prevent the material from cracking, bursting and breaking due to rapid heating. Thereby improving the quality of the finished product and reducing the breakage rate.

8. A scraper is installed under the dryer equipment, responsible for cleaning the equipment, and finally exporting the dust particles, thereby reducing the work intensity of the operator and reducing the equipment failure.

9. We will reasonably configure the models of positive pressure blower and negative pressure induced draft fan according to the length of the dryer, material moisture content, hot blast stove, hot blast temperature and other conditions. This is also the accumulation of our company for many years.

Note: Because the specific gravity of the drying material is different, the output will be different. Please refer to the technical staff for the final output.

The flap dryer is a kind of horizontal dryer. Drying equipment based on the principle of two-way conveying. The material flows from the head of the dryer through the feed hopper into the upper grid of the dryer. The feed hopper has the function of buffering and uniform distribution of the material. The material is evenly distributed on the grid, and the thickness of the material is 100mm-200mm. It runs smoothly to the end of the dryer, and the special flap mechanism of the flap dryer unloads the material into the lower layer smoothly, and then slowly runs to the head of the dryer, repeating this cycle, and shuttles inside the dryer many times. In operation, the distribution of materials in the dryer is more even and reasonable, and the hot air baking time is longer. After the materials are dried, they will be sent out from the tail of the machine.

The sand and gravel production line exported by our company to North Korea has begun production

North Korea’s sand and gravel production line equipment has begun large-scale production. The sand and gravel p...Sent to Sichuan 30m mesh belt dryer

The 30-meter long mesh belt dryer sent to Sichuan began to be loaded and shipped. The mesh belt dryer is a special dr...The pressure ball drying production line with an annual output of 200,000 tons is sent to Yuncheng,

The production line is fed by a loader to the production line, and is conveyed to the mixer via a belt conveyor to ...Delivery site of the flap dryer production line ordered by a customer in Yulin, Shaanxi

Our company is a mechanical enterprise mainly engaged in the production of ball pressing and drying equipment. The ...

Copyright © HENAN FUWOLIQIANG mechanical equipment Co., Ltd